Commercial Hydronic Radiators

Curved & Segmented

Curved Radiators and Segmented Radiators

Segmented Radiators

Mounting Systems

Wall mounting is the easiest way to install curved or segmented Runtal Radiators. These radiators are specially made with the proper bracketing required for a smooth- looking installation. Runtal recommends wall blocking and lockdown brackets for curved radiators to ensure secure mounting. Segmented Runtal Radiators are easily wall mounted with standard brackets, included with each order.

Floor Mounting along a curved wall is an alternative way to install Runtal Radiators. Floor mount brackets are specially manufactured to match the radiators in both quality workmanship and color. Floor Mounting is a cost effective way to install radiators along curved glass walls or other applications where wall mounting is not an option. For further details on these specialty radiators, contact your local Runtal Representative today.

Specifications: Field Curved Radiators

FIELD Curved Radiators

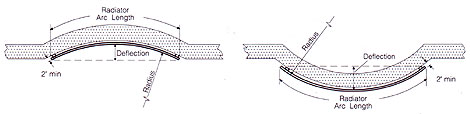

| CONCAVE | CONVEX |

|

|

| Project Name | Project Location |

| Tag. No | Quality | Radiator Model |

Radiator Arc Length |

Radius | Concave/ Convex |

Deflection | Connections | Color |

MINIMUM RADIATOR LENGTHS SHOWN (Maximum length in most cases is 22 feet)

| RADIUS | RADIUS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| General notes on FIELD curving: | Ordering notes for FIELD curving: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Specifications: Factory Curved Radiators

FACTORY Curved Radiators

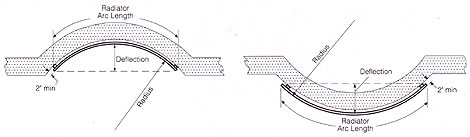

| CONCAVE | CONVEX |

|

|

|

| Project Name | Project Location |

| Tag. No | Quality | Radiator Model |

Radiator Arc Length |

Radius | Concave/ Convex |

Deflection | Connections | Color |

MAXIMUM RADIATOR LENGTHS FACTORY CURVABLE (Minimum length in all cases is 5 feet)

|

PANELS |

|

|

PANELS |

|

| General notes on FACTORY curving: | Ordering notes for FACTORY curving: | ||||||||||||||||||||||||

|

|

Colors & Finishes

Mounting Systems

Wall mounting is the easiest way to install curved or segmented Runtal Radiators. These radiators are specially made with the proper bracketing required for a smooth- looking installation. Runtal recommends wall blocking and lockdown brackets for curved radiators to ensure secure mounting. Segmented Runtal Radiators are easily wall mounted with standard brackets, included with each order.

Floor Mounting along a curved wall is an alternative way to install Runtal Radiators. Floor mount brackets are specially manufactured to match the radiators in both quality workmanship and color. Floor Mounting is a cost effective way to install radiators along curved glass walls or other applications where wall mounting is not an option. For further details on these specialty radiators, contact your local Runtal Representative today.